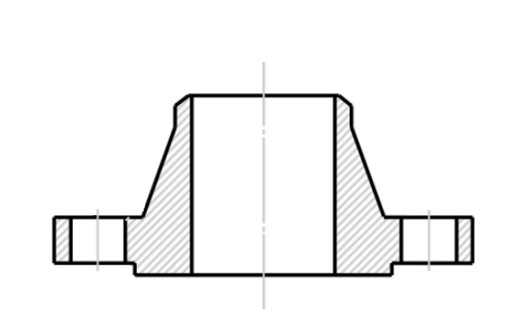

Weld Neck Flange

Weld neck flange (WN flange) has a neck that can relocated stress of the pipe, so to reduce the pressure that gathered in the flange bottom. It is compatible to the pipelines that works in high or low temperature and bear high pressure. Specially for the pipe or the valves when PN is larger than 2.5 Mpa.

Our Supply Range

Material: Carbon, Alloy and Stainless Steel

Standards: ASTM A105, ASTM A182

Sizes: 1/2'' to 24'', Customized up to 48''

Thickness: Schedule 10(S) to SCH 160

Pressure Ratings: Class 150 to 2500

Face Type: RF, RTJ

Two Shapes of Welding Neck Flange

Welding neck flange have two forms (shapes), one with reducing neck as we called reducing weld neck flange; One with a even diameter of typical long neck named as long neck weld flange.

Reducing Weld Neck Flange

As it's name it is like a combination of pipe reducer and flange, so it could be welded to a smaller pipe directly.

Long Weld Neck Flange

Simplified called as LWN flange, the neck part seems like a elongated pipe and connected to a flange. So in most cases it works as a nozzle for a column or a barrel.

You can choose for a normal thickness long welding neck flange or a heavy LWN flange that with bigger thickness and a differently shape.

Face Type

Like other flanges it has Raised Face (RF) Type and Ring Type Joint (RTJ).

Raised Face Weld Neck Flange

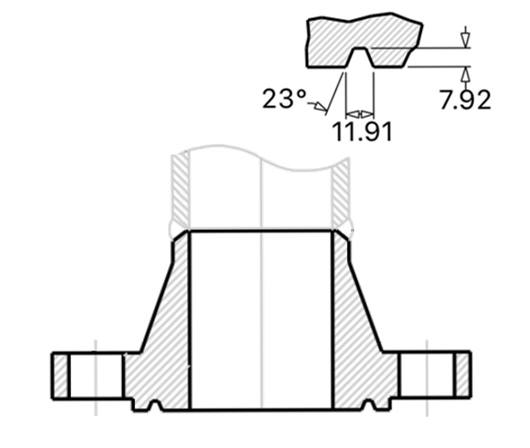

RTJ Weld Neck Flange

Raised face weld neck flange bottom side has a small portion surrounding the bore that protrudes from the face. Gasket seat will be placed in this raised area. Depending on the different pressure ratings, different height of raised face will be adopted. For example, 150# and 300# flange raised face height is 1/6'', above 300# the height will be above 1/4''.

The ring-joint type of WN flange has a special made groove, here you can place a metal gasket seat to seal the connects. So this type of SW flange is used in high temperature and high pressure services.

Standards Referred for WN flange

Material Standards

- ASTM A105/N For carbon steel weld neck flange

- ASTM A182 F11, F22 for alloy steel

- ASTM A182 F304 / F304L, F316 / F316L for stainless steel weld neck flange.

Manufacturing Standards

- ASME B16.5

- ASME B16.47

- BS 3293

- DIN 2630 PN 1 and PN 2.5, 2631 PN 6, 2632 PN 10, 2634 PN 16, 2634 PN 25, 2635 PN 40

Applications and Features

Weld neck flange mainly used in medium, high pressure pipes connecting, most butt weld flange with neck also called nipple flange.

Therefore, the installation cost of the welding flange, labor costs and auxiliary materials costs are higher, because there is more than one process.