Stainless Steel Flange

Stainless steel flange simplified as SS flange, it refers to the flanges that made of stainless steel. It is a mechanical component used primarily in piping systems to connect two sections of pipe or other equipment, providing a robust and reliable junction.

The common material standards and grades for stainless steel are ASTM A182 Grade F304/L and F316/L, with pressure ratings ranging from Class 150 to Class 2500. Stainless steel is utilized in more industries than carbon steel because it offers superior corrosion resistance and an aesthetically pleasing appearance.

Applications:

- Oil and Gas: Used in pipelines and processing facilities.

- Water Treatment: Common in systems handling potable water.

- Chemical Processing: Essential for systems requiring low contamination and corrosion resistance.

Benefits:

- Corrosion Resistance: Stainless steel is designed to resist rust and corrosion.

- Strength: Provides a strong connection under high-pressure conditions.

- Versatility: Available in various types and sizes for diverse applications.

Connections Types for Stainless Steel Flanges

Stainless steel flanges also ranged with slip on flange, weld neck flange, blind flange, socket weld flange and threaded pipe flange.

Weld Neck Flange

Slip On Flange

Blind Pipe Flange

Socket Weld Flange

Lap Joint Flange

Threaded Pipe Flange

Generally they could be called stainless steel pipe flange, or stainless steel plate flange.

About Stainless Steel

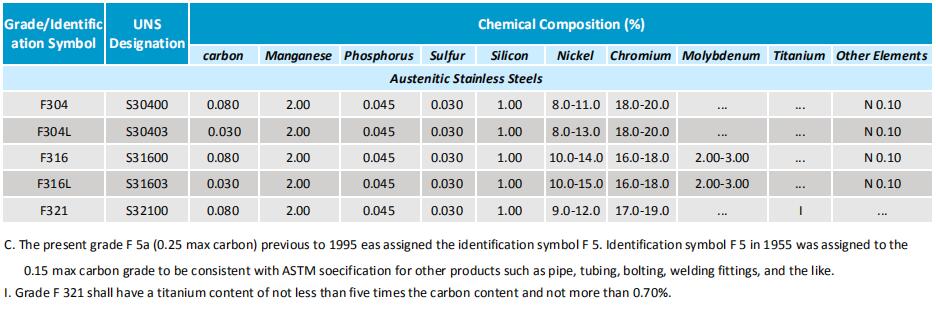

In metallurgy, stainless steel is also known as inox steel or inoxidizable steel. It is an alloy made primarily of steel with a high content of chromium and nickel, with the following minimum and maximum composition standards:

- Minimum Chromium (Cr): 10.5%

- Minimum Nickel (Ni): 8%

- Maximum Carbon: 1.5%

Stainless steel flanges are renowned for their excellent corrosion resistance, primarily due to the presence of chromium. As the chromium content increases, the corrosion resistance improves.

Additionally, the inclusion of molybdenum enhances corrosion resistance against reducing acids and pitting in chloride-rich environments. Different grades of stainless steel are available, each with varying chromium and molybdenum compositions tailored to specific environmental conditions.

Advantages:

- Excellent resistance to corrosion and staining

- Low maintenance requirements

- Bright, familiar luster

- High tensile strength

ASTM A182 - Popular Standard for Stainless Steel Pipe Flange

For stainless steel pipe flange, common use material is ASTM A182 F304/L and F316/L.

ASTM A182: It refers to forged and rolled alloy and stainless steel pipe flanges, fittings, valves and parts for high temperature service. And it includes several grades of austenitic and ferritic-austenitic stainless steels.

Dimensions: 1/2'' to 2'', 3'', 4'', 6'' and up to 48''.

Wall thickness schedule: SCH 10S, SCH 40S, SCH STD, SCH 80S

Pressure ratings: 150#, 300#, 600#, 900#, 1500#, 2500#

Material Grade: F304, F316, F321 and more

Chemical Composition for F304 and F316 SS Flange

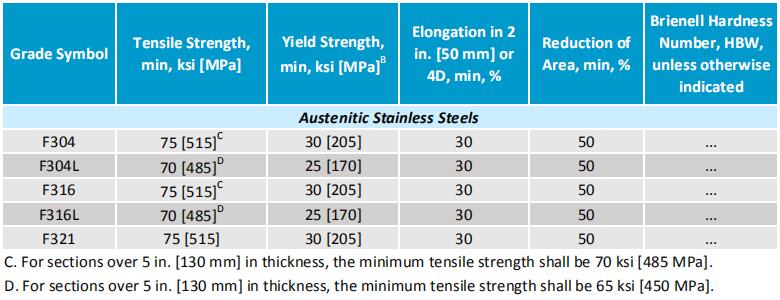

Mechanical Properties

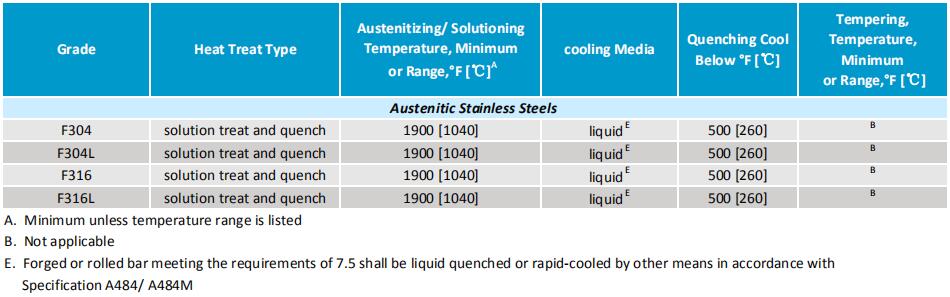

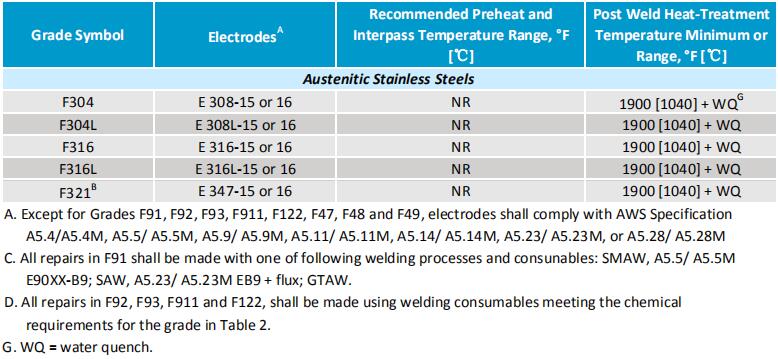

Heat Treatment for SS Flange

Welding Repair Requirements for Stainless Flange

304 Stainless Steel Flange Features

304 stainless steel is a highly versatile material that is commonly used to manufacture equipment and components requiring excellent overall performance, including corrosion resistance and formability. In China, 304 stainless steel is referred to as 0Cr19Ni9 or 0Cr18Ni9, correlating to its composition of 19% chromium and 9% nickel.

Application:

304 stainless steel is a widely used chromium-nickel alloy known for its excellent corrosion resistance, heat resistance, low-temperature strength, and mechanical properties. It performs well in atmospheric conditions, but in industrial or heavily polluted environments, it should be cleaned regularly to prevent corrosion.

This stainless steel is suitable for food processing, storage, and transportation, thanks to its good processing properties and weldability. It is commonly found in applications such as plate heat exchangers, bellows, household goods, building materials, chemicals, and the food industry.

316 SS Pipe Flange Features

Compared to 304 stainless steel, 316 stainless steel contains additional nickel and molybdenum, known in China as 18Cr-12Ni-2.5Mo steel. Typically, 316 stainless steel has an extra 2.0 to 3.0 percent molybdenum compared to 304. This molybdenum enhances the material's resistance to high temperatures.

As a result, 316 stainless steel exhibits superior corrosion resistance, atmospheric corrosion resistance, and high-temperature strength. It is particularly suitable for use in harsh environments, thanks to its excellent work-hardening properties and non-magnetic nature.

Sulfuric acid is one of the largest tonnage industrial chemical manufactured. At room temperature Type 304 is only resistant to 3% acid while Type 316 is resistant to 3% acid up to 50 °C and 20% acid at room temperature. So Type 304 is rarely used in contact with sulfuric acid. Type 904L and Alloy 20 are resistant to sulfuric acid at even higher concentrations above room temperature.

Application:

316L stainless steel flanges offer excellent corrosion resistance, outperforming 304 stainless steel in seawater and various other media. This grade is often referred to as "marine grade" stainless steel, although it is not resistant to warm seawater.

These flanges are ideal for equipment exposed to sulfuric acid, phosphoric acid, formic acid, and acetic acid. Common applications include marine environments, pumping systems, chemical production, the food industry, irrigation, and various stainless steel pipeline systems.

Manufacturing Types:

316L stainless steel flanges are available in forged and cast types, with the forged type being the most commonly adopted in practice.

Referred Standards:

- B16.5 Dimensional standard for steel pipe flanges and flanges fittings

- B16.34 Valves connect by flanges, threaded and welding end

- B16.47 Large diameter steel flanges