Carbon Steel Flange

Carbon Steel Flange and end flange connectors are basically made of carbon steel. Common standards include ASTM A694, ASTM A105N (SA105N), MSS SP-44, DIN 2533. Accompanying pressure ratings are from class 150 to 2500.

Carbon steel is a steel with carbon content up to 2.1% by weight. Where in AISI defines:

- No alloy element (minimum content) required, as of Cr, Mo, Ni, Ti, Va and etc.

- Specified minimum of Cu shall not exceed 0.04%.

- Maximum Mn 1.65%, Si 0.06%.

As carbon element content increases, the steel will become harder and stronger after heat treatment. On the contrary, it become less ductile. Where if without heat treatment, higher carbon will reduce weldability.

Carbon steel may include alloy steels in case it is not used as stainless steel.

Refers to Mild Steel or Low Carbon Steel Pipe Flanges

Carbon steel pipe flanges usually adopt mild steel or low carbon steel, as it includes small percentage of carbon, strong and tough but not readily tempered. Which with lower cost and material could be used for many applications.

- Low carbon steel: C content at 0.005% to 0.3%.

- Medium carbon steel: 0.3 to 0.8% of Carbon.

- High carbon steel: 0.8-2.0% of carbon.

- Ultra high carbon steel: 1.25% to 2.0% of C.

ASTM A105N (SA105N) Carbon Steel Pipe Flanges

ASTM A105 steel grade is a typical common material (mild carbon steel) for forged carbon steel flange, it used in a lot of places for ambient and higher-temperature service in pressure systems. This material is durable, cost lower, and difficult to break. In case used in a stainless steel piping system it shall be adapted with a lap joint end ring.

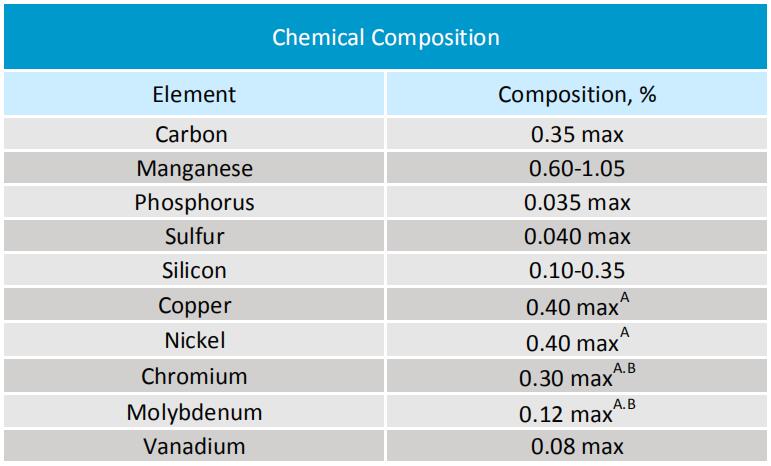

Chemical composition of A105 carbon steel pipe flanges

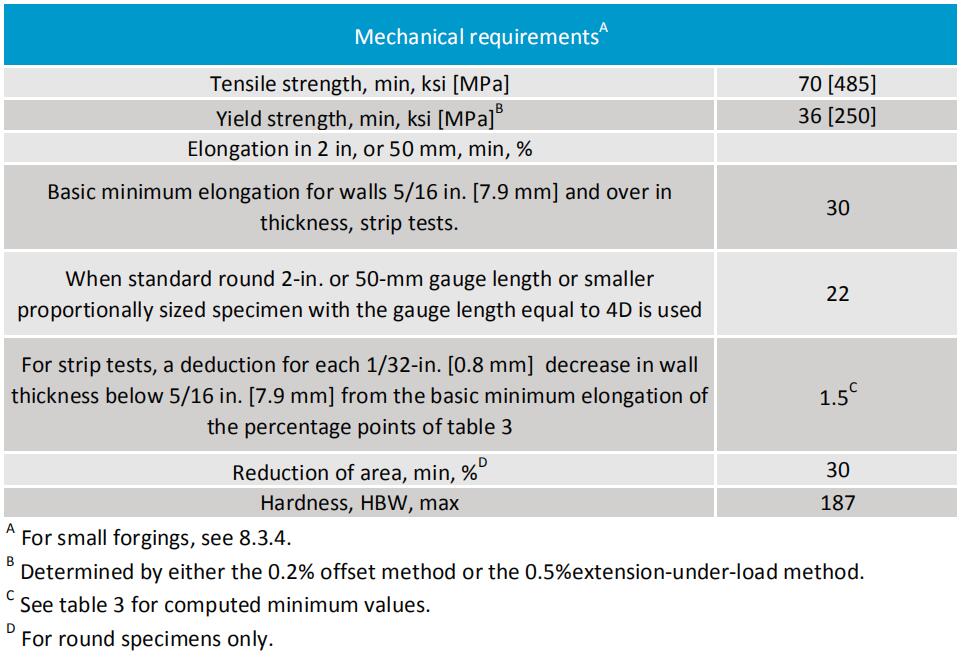

Mechanical Strength

ASTM A350 (SA350) LF2 - Low Temperature Use

Designed specifically for low-temperature usage, this carbon steel grade shares close similarities with ASTM A105N (SA105N) grade. This grade requires notch durability testing, and applicable for many industries.

This carbon steel grade also applied to low temperature carbon steel fittings.

ASTM A694 - A Rigorous Carbon Steel Flange Material

The standards set for ASTM A694 is more rigorous than the two above. Its requirements for high-pressure fluid transmission of oil and gas piping is stringent. Because of the stringent conditions with the steel grade, manufacturers have to develop an even stronger steel for both low temperatures and high temperatures. There is a minimum yield strength that comes with all grade of A694.

Manufacturing Types and Standards

Carbon Steel Flanges are manufactured either by forging or by casting.

Differences between forged steel flange and cast iron flange

- Forging process is more expensive than the cast iron process

- Casting iron can be manufactured to fit different complex profiles

- Forging process doesn't lead to the manufacture of big or uneven brain

- Cast iron flange is used exclusively for non-pressure pipelines, while forged Steel Flange is used in higher pressure pipeline

- The centrifugal machine is used to manufacture high precision cast iron flange than standard cast flanges

- Forged Steel can easily be cut, and it can withstand higher tensile strength

- Overall, forged steel is better than cast iron flanges in terms of performance as it comes with a better shape and also much lower carbon content which leads to less rusting.

Referred Standards:

- B16.5 Dimensional standard for steel pipe flanges and flanges fittings

- B16.34 Valves connect by flanges, threaded and welding end

- B16.47 Large diameter steel flanges

- SP44 Standard for steel pipe line flanges

- API 605 large diameter carbon steel flanges

Coating Types

There are several types of coatings to protect carbon steel flange from rusting or corrosion:

- Anti-rust painting

- Oil Varnished

- Electric zinc coated (White or yellow zinc)

- Alloy material coated (Lined or Clad)

Carbon Steel Flange Types

- Weld Neck Flange

- Slip On Flange

- Blind Flange

- Socket Weld Flange

- Threaded Flange

- Reducing Flanges