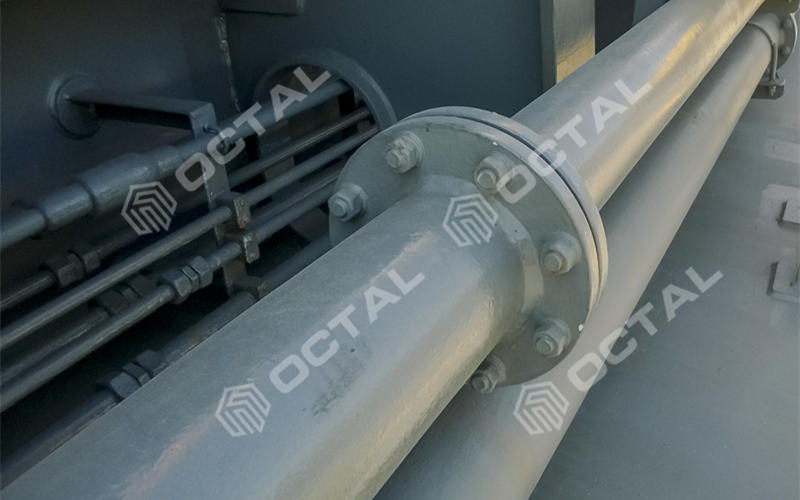

Flanged Joint Pipe / Flanged Pipe

Flanged pipe (Flanged Joint Pipe) is a type of piping system that features flanges at the ends of the pipes, allowing for easy connection to other piping components or equipment. Flanges are flat pieces of metal with holes for bolts, enabling the pipes to be securely fastened together. Here are some key characteristics and uses of flanged pipes:

1. Connection Method: Flanged pipes are connected using bolts and gaskets, providing a strong and leak-proof joint. This makes them suitable for high-pressure applications.

2. Types of Flanges: Common types of flanges used with flanged pipes include weld neck flanges, slip-on flanges, socket weld flanges, and flat flanges. Each type has specific applications based on the requirements of the piping system.

3. Materials: Flanged pipes can be made from various materials, including carbon steel, alloy steel, stainless steel, and ductile iron, depending on the application and environmental conditions.

4. Applications: Flanged pipes are widely used in various industries, including oil and gas, water treatment, chemical processing, and HVAC systems, due to their ease of installation and maintenance.

5. Above-Ground Use: Flanged pipes are primarily installed above ground, as their rigid joints may not perform well in underground applications where ground movement and pressure variations can occur.

6. Maintenance: The design of flanged joints allows for easier maintenance and repair, as individual sections of the piping system can be removed or replaced without needing to cut the pipe.

Overall, flanged pipes provide a reliable and efficient solution for connecting piping systems in a variety of industrial applications.

There are several types of flanges used to create a complete flanged joint pipe, including weld neck flanges, slip-on flanges, socket weld flanges, and flat flanges. These flanges are welded onto the pipe ends.

Material types

Carbon steel flanged joint pipe: Flange material in ASTM A105N, ASTM A350 LF2, LF3, ASTM A694 F42,F46, F52, F60 to F70. Pipe material in ASTM A53, A106, A333 and API 5L;

Alloy flanged steel pipe: Flange material in ASTM A182 F5, F9, F11, F22, F91; Alloy pipes in ASTM A335 P5, P9, P11, P22, P91 etc.

Stainless flanged steel pipe: Flange material in 304/304L, 316/316L. Stainless steel pipe material in ASTM A312 TP304/304L, TP316/316L.

Flanged Joint Pipe used on above ground

Flanged steel pipe is primarily designed for above-ground installation. It is not well-suited for underground use due to the rigidity of the joints. In underground structures, uneven settlement or stress can lead to deformation of the flanged connections, potentially resulting in pipeline failure.

Application

Industrial Plants

Water transporation system

Sewage disposal plants

Fire protection pipelines

Shipbuilding System

Pumping stations

Wastewater treatment plants

Flanged Fittings

Flanged fittings includes:

Flanged Pipe Bend

Flanged Tee

Flanged Reducer

Flanged Elbow

Flanged fittings are flanged base pipe fittings, same with flanged joint pipe, the fittings ends butt welded with flange to form a flange connection.

Supply Range for Flanged Joint Pipe

Pipe Standard: ASTM A53, ASTM A106, ASTM A333 Grade 6, ASTM A335, API 5L

Flange Material: ASTM A105N, ASTM A350 LF2, ASTM A182, F5, F9, F11, F22, F91

Flange Type: Weld Neck Flange, Slip On Flange, Flat Flange,

Pressure class: PN6 to PN60, Class 150#, 300#, 600#, 900#, to 2500#.

Manufacturing standard: ASME B16.5, ASME B16.47 A, B, EN 1092-1

Outer diameter: NPS 1/2 inch to NPS 48 inch, 21.3 mm to 1219mm

Wall thickness: SCH 10, SCH 20, SCH STD, SCH 40, SCH 80, to SCH160, SCHXX; 1.24mm up to 1 inch, 25.4mm

Range of length: Customized. SRL, DRL, 6m, 12m.

Coating: Black paint, Varnished, Epoxy Coating, Polyethylene Coating, FBE, 3PE, CRA Clad and Lined, Fluoroplastic Lining